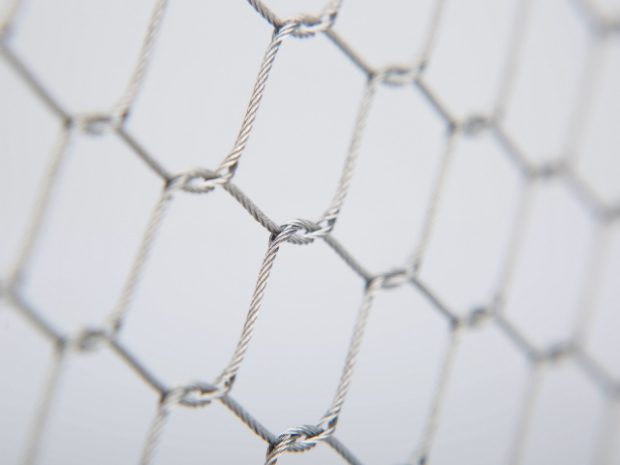

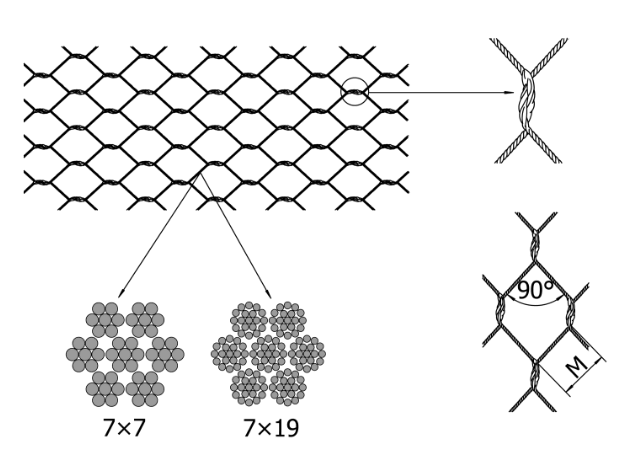

Hand woven mesh is made of stainless steel wire ropes that are twisted and crossed together. Compared with wire rope ferrule mesh, it has better overall integrity and higher transparency and is suitable for places with higher visual effect and safety protection requirements. Its integrated structure allows it to be better stretched, twisted and create more innovative decorative effects, without compromising strength or safety.

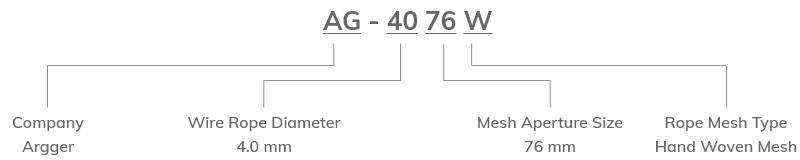

We can provide rope mesh materials with different mesh aperture sizes and wire rope diameters, and design custom solutions based on your specific applications.

Each of our products undergoes stringent inspections before leaving the factory to ensure their compliance with AISI 304, 316, 316L, and ISO/TS 15510:2003 standards.

| Type | C (%) | Si (%) | Mn (%) | Cr (%) | Ni (%) | S (%) | P (%) |

|---|---|---|---|---|---|---|---|

| 304 | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | 17.0-19.0 | 8.0-11.0 | ≤ 0.03 | ≤ 0.035 |

| 304L | ≤ 0.03 | ≤ 1.0 | ≤ 2.0 | 17.0-19.0 | 8.0-12.0 | ≤ 0.03 | ≤ 0.035 |

| 316 | ≤ 0.08 | ≤ 1.0 | ≤ 2.0 | 16.0-18.5 | 10.0-14.0 | ≤ 0.03 | ≤ 0.035 |

| 316L | ≤ 0.03 | ≤ 1.0 | ≤ 2.0 | 16.0-18.0 | 12.0-15.0 | ≤ 0.03 | ≤ 0.045 |

When the application requires high resistance to chloride ion corrosion and heat, 316 stainless steel is preferred. That's because 316 stainless steel contains the element molybdenum (Mo), which forms a denser and more stable passive film on the metal surface, thus effectively enhancing the stainless steel's resistance to chloride ion corrosion.

| Model | Wire Rope Structure | Wire Rope Diameter | Mesh Aperture | Minimum Breaking Force | ||

|---|---|---|---|---|---|---|

| inch | mm | inch | mm | (kN) | ||

| XN-40203W | 7 × 19 | 5/32" | 4 | 8" × 8" | 203 × 203 | 10.7 |

| XN-40152W | 7 × 19 | 5/32" | 4 | 6" × 6" | 152 × 152 | 10.7 |

| XN-40127W | 7 × 19 | 5/32" | 4 | 5" × 5" | 127 × 127 | 10.7 |

| XN-40102W | 7 × 19 | 5/32" | 4 | 4" × 4" | 102 × 102 | 10.7 |

| XN-4090W | 7 × 19 | 5/32" | 4 | 3.6" × 3.6" | 90 × 90 | 10.7 |

| XN-4076W | 7 × 19 | 5/32" | 4 | 3" × 3" | 76 × 76 | 10.7 |

| XN-32152W | 7 × 19 | 1/8" | 3.2 | 6" × 6" | 152 × 152 | 7.38 |

| XN-32127W | 7 × 19 | 1/8" | 3.2 | 5" × 5" | 127 × 127 | 7.38 |

| XN-32120W | 7 × 19 | 1/8" | 3.2 | 4.7" × 4.7" | 120 × 120 | 7.38 |

| XN-32102W | 7 × 19 | 1/8" | 3.2 | 4" × 4" | 102 × 102 | 7.38 |

| XN-3290W | 7 × 19 | 1/8" | 3.2 | 3.6" × 3.6" | 90 × 90 | 7.38 |

| XN-3276W | 7 × 19 | 1/8" | 3.2 | 3" × 3" | 76 × 76 | 7.38 |

| XN-3260W | 7 × 19 | 1/8" | 3.2 | 2.4" × 2.4" | 60 × 60 | 7.38 |

| XN-3251W | 7 × 19 | 1/8" | 3.2 | 2" × 2" | 51 × 51 | 4.18 |

| XN-24152W | 7 × 7 | 3/32" | 2.4 | 6" × 6" | 152 × 152 | 4.18 |

| XN-24127W | 7 × 7 | 3/32" | 2.4 | 5" × 5" | 127 × 127 | 4.18 |

| XN-24102W | 7 × 7 | 3/32" | 2.4 | 4" × 4" | 102 × 102 | 4.18 |

| XN-2490W | 7 × 7 | 3/32" | 2.4 | 3.6" × 3.6" | 90 × 90 | 4.18 |

| XN-2476W | 7 × 7 | 3/32" | 2.4 | 3" × 3" | 76 × 76 | 4.18 |

| XN-2460W | 7 × 7 | 3/32" | 2.4 | 2.4" × 2.4" | 60 × 60 | 4.18 |

| XN-2451W | 7 × 7 | 3/32" | 2.4 | 2" × 2" | 51 × 51 | 3.17 |

| XN-2076W | 7 × 7 | 5/64" | 2 | 3" × 3" | 76 × 76 | 3.17 |

| XN-2060W | 7 × 7 | 5/64" | 2 | 2.4" × 2.4" | 60 × 60 | 3.17 |

| XN-2051W | 7 × 7 | 5/64" | 2 | 2" × 2" | 51 × 51 | 3.17 |

| XN-2038W | 7 × 7 | 5/64" | 2 | 1.5" × 1.5" | 38 × 38 | 2.17 |

| XN-16102W | 7 × 7 | 1/16" | 1.6 | 4" × 4" | 102 × 102 | 2.17 |

| XN-1676W | 7 × 7 | 1/16" | 1.6 | 3" × 3" | 76 × 76 | 2.17 |

| XN-1660W | 7 × 7 | 1/16" | 1.6 | 2.4" × 2.4" | 60 × 60 | 2.17 |

| XN-1651W | 7 × 7 | 1/16" | 1.6 | 2" × 2" | 51 × 51 | 2.17 |

| XN-1638W | 7 × 7 | 1/16" | 1.6 | 1.5" × 1.5" | 38 × 38 | 2.17 |

| XN-1630W | 7 × 7 | 1/16" | 1.6 | 1.2" × 1.2" | 30 × 30 | 2.17 |

| XN-1625W | 7 × 7 | 1/16" | 1.6 | 1" × 1" | 25.4 × 25.4 | 1.22 |

| XN-12102W | 7 × 7 | 3/64" | 1.2 | 4" × 4" | 102 × 102 | 1.22 |

| XN-1276W | 7 × 7 | 3/64" | 1.2 | 3" × 3" | 76 × 76 | 1.22 |

| XN-1251W | 7 × 7 | 3/64" | 1.2 | 2" × 2" | 51 × 51 | 1.22 |

| XN-1238W | 7 × 7 | 3/64" | 1.2 | 1.5" × 1.5" | 38 × 38 | 1.22 |

| XN-1230W | 7 × 7 | 3/64" | 1.2 | 1.2" × 1.2" | 30 × 30 | 1.22 |

| XN-1225W | 7 × 7 | 3/64" | 1.2 | 1" × 1" | 25.4 × 25.4 | 1.22 |

| XN-1220W | 7 × 7 | 3/64" | 1.2 | 0.8" × 0.8" | 20 × 20 | 1.22 |