As a commonly used industrial material, wire rope has high strength, high stiffness and good wear resistance, and is widely used in the fields of safety protection and building decoration. Wire rope mesh, as a form of wire rope application, is also getting more and more attention because of its superior visibility, load-bearing capacity and aesthetic appearance. However, when choosing wire rope mesh, several factors need to be considered, such as the required strength, stiffness, visibility and cost. We will introduce how to choose the right rope mesh wire rope diameter based on the actual use and requirements, as well as the characteristics and applications of commonly used wire rope structures and wire rope diameters.

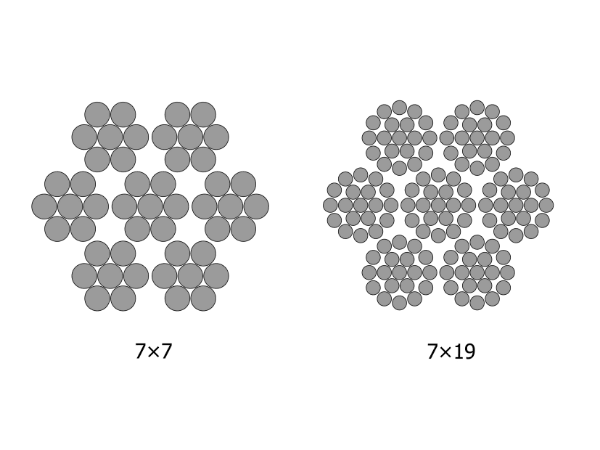

Common wire ropes are available in 2 structures: 7 × 7 and 7 × 19. Among them, 7 × 7 structure wire rope consists of 7 steel wire strands and each strand is braided by 7 steel wires; 7 × 19 structure wire rope consists of 7 steel wire strands and each strand is braided by 19 steel wires; The larger the diameter of a wire rope, the bigger its breaking force, the greater the number of strands, the better its flexibility. When choosing wire rope mesh, it is necessary to consider various factors according to the actual use and requirements to determine the most suitable wire rope structure and wire rope diameter.

The structure with wire rope diameter of 1.2 mm, 1.6 mm, 2.0 mm and 2.4 mm is 7 × 7; while the structure with wire rope diameter of 3.2 mm and 4.0 mm is 7 × 19.

For small birds, the common wire rope diameter is 1.2 mm; For large birds and poultry, the wire rope diameters are 1.6 mm and 2.0 mm.

For primates (such as monkeys, gorillas) and large herbivores (like giraffes and zebras), wire rope diameters of 1.6 mm, 2.0 mm and 2.4 mm are highly recommended.

For tiger, leopard and lion, wire rope diameters of 2.4 mm and 3.2 mm are highly recommended.

Generally, the stair railing net is used with wire rope diameters of 2.4 mm and 3.2 mm.

When a steel wire rope is assembled and subjected to a load, it follows Hooke's Law; the elastic stretch will be proportional to the applied load. In other words, the greater the load, the greater the elastic elongation. The resistance of the steel wire rope to this elastic elongation is determined by its modulus of elasticity. The modulus of elasticity is an inherent property of a material that represents its ability to undergo elastic deformation when subjected to a force. The higher the modulus of elasticity, the greater the resistance of the material to elastic elongation.

The elastic stretch can be calculated by the following formula:

Elastic stretch = (W × L) / (E × A)

W = Applied load ( kN )

L =Cable length (mm)

E = Strand modulus ( kN/mm2)

A = Cable area = (D2 × pi) / 4 (where D= Cable diameter mm)

Typical values for E are:

7 × 7 = 57.3 kN/mm2

7 × 19 = 47.5 kN/mm2

If you want to improve the load-bearing capacity and stability of the wire rope, you can choose a wire rope with a larger modulus of elasticity. In this way, when subjected to a load of the same size, the degree of deformation of the wire rope will be smaller, thus improving its load-bearing capacity and stability.

BL: It refers to the stress that, when applied to a structural member, is just enough to fracture or rupture it, also known as the ultimate load.

SWL: It refers to the load that a wire rope can withstand without causing any type of damage to it. It is important to note that the safe working load is much lower than the breaking strength.

What are the application field

What are the application field

How to determine the load-bear

How to determine the load-bear

What are animal enclosures mad

What are animal enclosures mad

How Choose the Best Stainless

How Choose the Best Stainless