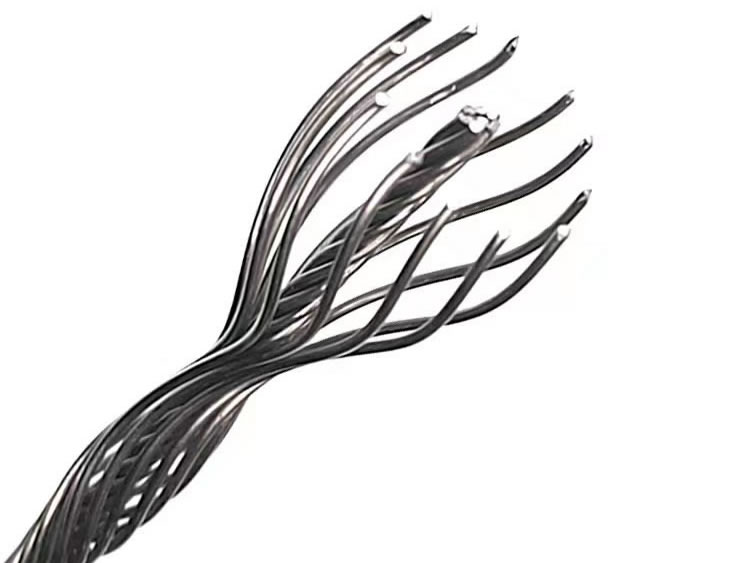

Stainless steel wire ropes are renowned for their strength, durability, and outstanding flexibility. They are highly resistant to corrosion and are typically used in high-end applications across a range of industries including construction, aviation, aerospace, and telecommunications. Here, we will explore what makes stainless steel wire rope the ideal choice for high-end applications.

Stainless steel wire rope is incredibly strong and durable and is able to withstand harsh environmental conditions like extreme temperatures, corrosion, and abrasion. It is much more resilient than other material used in applications that require a high degree of strength such as those in the energy industry and the automotive industry.

Stainless steel is well known for its excellent corrosion resistance, making it the perfect choice for applications that need reliable service and where corrosion could be an issue. The steel’s superior corrosion resistance means it will last a long time in even the most extreme conditions, enabling it to be used in situations that require prolonged periods of operation.

Stainless steel wire rope has incredibly high flexibility which makes it an ideal choice for projects that require precise positioning and maneuverability. It also requires very low amounts of maintenance, meaning that the cost of upkeep is significantly less than that of other materials.

Due to the strength and durability of stainless steel, wire rope used in projects that involve lifting heavy objects offer significant improvements in safety. This is particularly beneficial in construction and mining industries, where the heavy machinery used on a daily basis requires strong and reliable ropes to ensure maximum safety levels.

Overall, the benefits of using stainless steel wire rope in high-end applications cannot be overstated. Its incredible strength and durability, unbeatable corrosion resistance, high flexibility coupled with low maintenance costs, and improved safety makes it the clear choice for any project.

What are the application field

What are the application field

How to determine the load-bear

How to determine the load-bear

What are animal enclosures mad

What are animal enclosures mad

How Choose the Best Stainless

How Choose the Best Stainless